Aggancio Flex

AGGANCIO FLEX

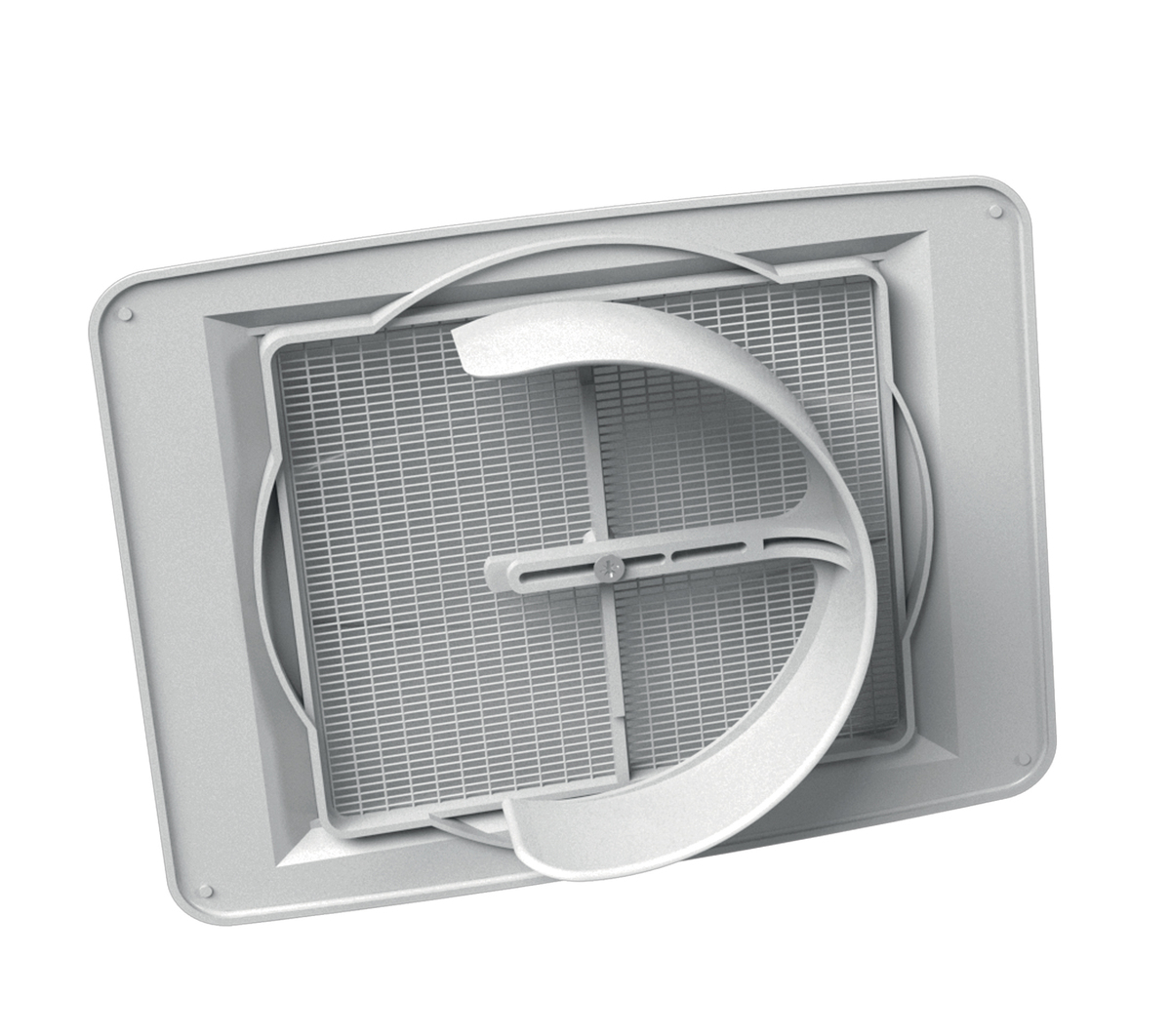

Our gratings are equipped with Aggancio Flex, an innovative spring with an elastic mouth of variable geometry for fast and stable mounting in holes or tubes of different diameters.

The gratings - plastic or metal - equipped with the innovative Aggancio Flex, constitute an effective solution that replaces both the commonly marketed gratings with fixed inlet diameters as well as those with metal springs.

ADVANTAGES OF INSTALLATION

The Aggancio Flex:

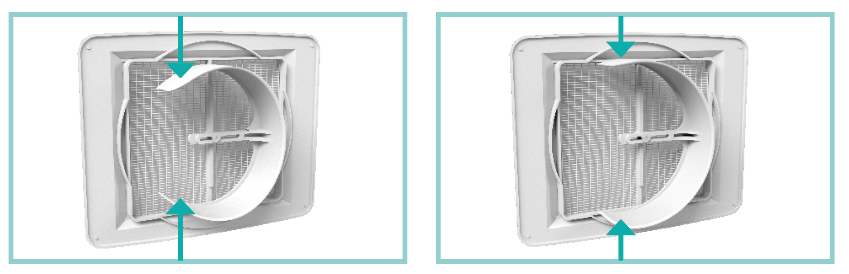

- Allows for quick and easy installation of the grating to the tube with immediate stability and adherence to the wall due to the depth of the inlet to spring which is 40 mm. It also allows easy rotation of the grating for an immediate orientation of the fins.

- Allows easy application even to the holes made on hollow bricks, chipped and irregular holes or without tubes.

- Allows the installation and the stability of the grating even in plasterboard panels of only 15 mm without damaging them during disassembly (the traditional springs would not be able to hook on because they would fall into empty space.

- Facilitates the removal and reinsertion of the grating for periodic safety inspections without being able to injury or cut as could happen with metal springs.

- Does not rust.

- It is applicable to plastic or metal gratings.

AGGANCIO FLEX FOR AIRPLAK

AGGANCIO FLEX FOR GRATINGS 175

AGGANCIO FLEX FOR GRATINGS 115

AGGANCIO FLEX FLEXIBILITY DETAIL

The elastic inlet made of particularly resistant and flexible synthetic material fits the circumference of the inner tube or hole in which it is inserted pertaining to more than half of it.

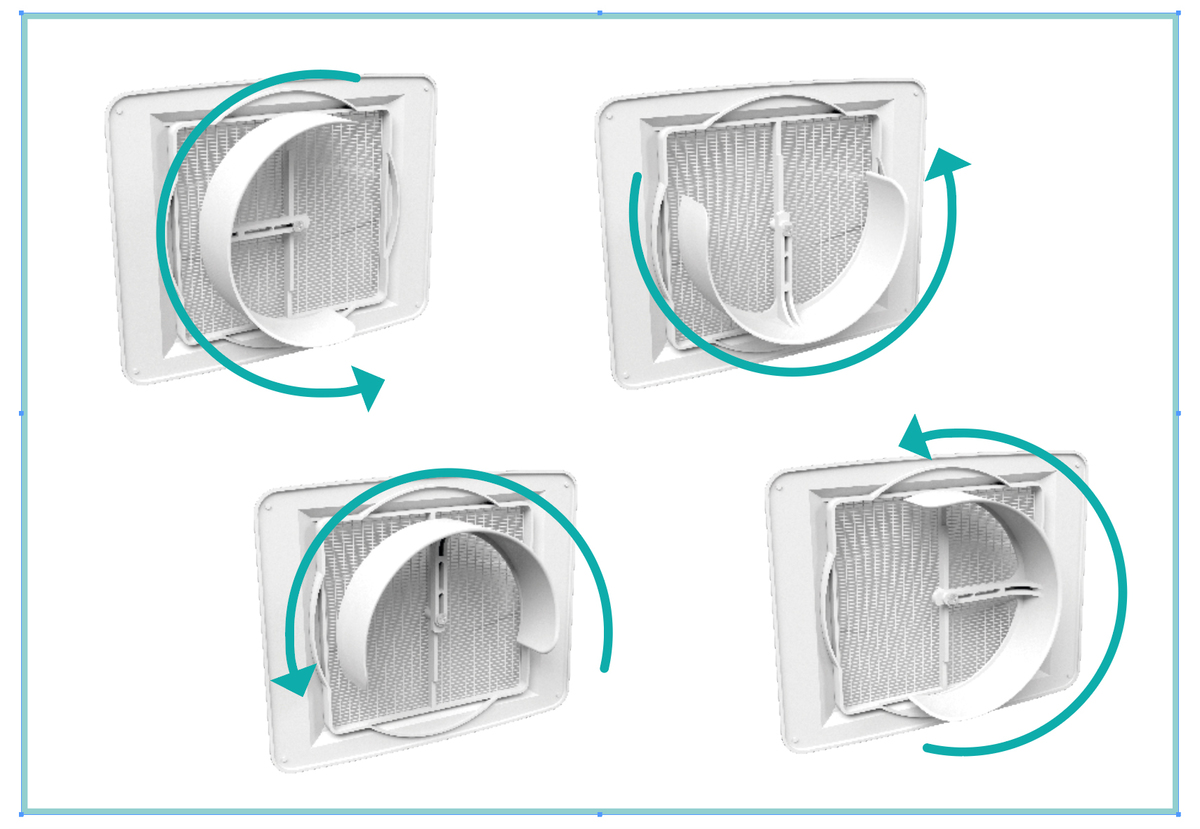

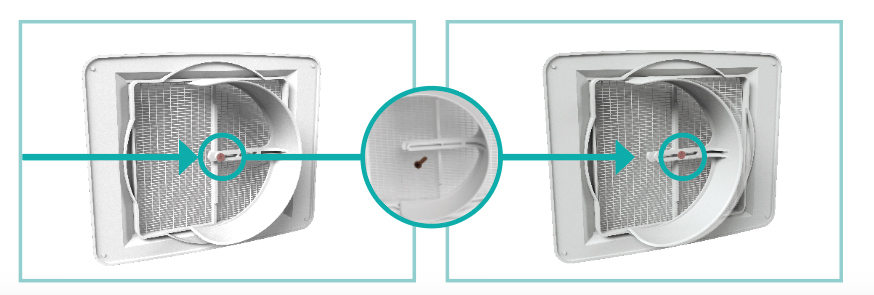

AGGANCIO FLEX ROTATION DETAIL

This innovative spring on the market allows the shifting and decentralized positioning of the grating to be applied:

- to a hole made too close to the ceiling or to a wall

- to cover any chipped masonry

- to be able to cover with the targeted placement of the AIRPLAK not restored paint.

The mounting is accomplished by simply loosening the screw connection to the grating, by sliding the spring along the sled buttonhole of the arm and screwing.

AGGANCIO FLEX MOVING DETAIL

To position the AIRPLAK diffuser in the right position, loosen the central screw of the Aggancio Flex and horizontally scroll the arm along the axis of the AIRPLAK. Once you have identified the optimal distance tighten the screw.

EXAMPLE OF INSTLLATION

In the sequence example is the case of a hole for the air intake system realized in a critical position, too close to the angle of the wall and with round grating cut to be installed.

In cases like this, Aggancio Flex lends itself to realize a state of the art mounting of the grating: it is sufficient to loosen the central screw and scroll horizontally to the arm of the Aggancio Flex along the axis of the AIRPLAK.

Place the Aggancio Flex at the required distance, partially screwing the screw to configure the desired position.

With the screw partially tightened, if necessary, begin to rotate the Aggancio Flex in order to obtain the right position.

Reached the correct position, tighten the screw to lock the movement.

Insert the AIRPLAK into the hole.

Detail of the placement of the Aggancio Flex into the hole.

Mounting concluded: application of the AIRPLAK diffuser done to perfection.